How an Optical Fibre Diameter Analyser Boosts Top Quality Control in Fibre Manufacturing

The combination of an Optical Fibre Diameter Analyser into Fibre production processes stands for a considerable advancement in quality assurance methods. By providing real-time, specific measurements of Fibre sizes, this technology resolves the important requirement for uniformity in manufacturing criteria. With its capability to promptly determine deviations and timely corrective procedures, the analyser not only improves product dependability yet likewise adds to general functional performance. As industries significantly focus on high quality and compliance, comprehending the full effect of such advancements becomes necessary. What implications could this have for the future of Fibre manufacturing?

Relevance of Fibre Diameter Dimension

Precise dimension of Fibre Diameter is important in the field of optical Fibre technology, as it directly influences the performance and reliability of Fibre optic systems. The Diameter of an optical Fibre impacts its light-carrying capability, attenuation, and overall transmission efficiency. Precision in measuring Fibre Diameter makes sure that the optical residential properties are kept within defined tolerances, which is important for optimal signal integrity.

Variants in Fibre Diameter can lead to increased losses due to spreading and modal diffusion, affecting the quality of data transmission. In high-speed interaction systems, such disparities can cause considerable degradation of signal quality, bring about information errors and reduced efficiency. Additionally, consistent Fibre Diameter is essential for compatibility with adapters and splicing innovations, which are essential components of Fibre optic networks.

Quality control procedures in Fibre manufacturing heavily rely on precise Diameter dimensions to ensure conformity with industry requirements. By implementing durable measurement methods, producers can boost product integrity, minimize waste, and boost overall system efficiency. Hence, the significance of Fibre Diameter measurement can not be overemphasized, as it acts as a keystone in the development of optical Fibre modern technology and its applications in contemporary interaction networks.

How the Analyser Functions

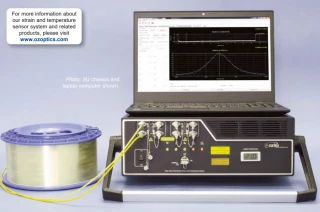

The reliable measurement of Fibre Diameter relies upon advanced logical methods that make sure accuracy and reliability in optical Fibre manufacturing (optical fibre diameter analyser). The Optical Fibre Diameter Analyser utilizes a mix of laser modern technology and advanced picture handling formulas to accurately evaluate the Diameter of fibers as they are generated

At first, a laser beam of light is directed at the moving Fibre, producing a cross-sectional darkness. The analyser records this darkness using high-resolution cams placed purposefully along the production line. The captured pictures are after that refined in real-time to determine the Fibre's Diameter with exceptional accuracy.

The system utilizes advanced formulas that make up numerous variables, consisting of variants in light strength and ecological problems, to boost dimension integrity. It can discover minute modifications in Diameter, such as changes that may happen throughout the production process.

In addition, the analyser is qualified of taking care of several fibres at the same time, enhancing throughput without compromising precision. By giving immediate comments on the Diameter, the Optical Fibre Diameter Analyser plays an important role in maintaining rigorous quality assurance requirements, guaranteeing that the final item satisfies industry requirements and client requirements.

Advantages of Real-Time Tracking

While traditional approaches of checking Fibre Diameter commonly involve taxing post-production checks, real-time tracking considerably boosts the effectiveness and quality of optical Fibre manufacturing. optical fibre diameter analyser. This aggressive method permits makers to identify variances in Fibre Diameter as they take place, as opposed to waiting till production is full to evaluate top quality

By constantly gauging the Diameter throughout production, makers can ensure that the fibres fulfill strict requirements, resulting in lowered variability and enhanced consistency. Real-time tracking additionally enables prompt corrective activities to be taken, minimizing waste and stopping malfunctioning fibres from getting in the supply chain.

Furthermore, this browse around this site innovation promotes enhanced data collection and evaluation, giving insights into manufacturing fads and potential areas for enhancement. Such data-driven decision-making encourages manufacturers to enhance procedures and keep high standards of quality control.

In enhancement, real-time surveillance cultivates a culture of continuous improvement within the production atmosphere. Workers are extra involved when they can see the influence of their operate in real-time, leading to heightened accountability and a commitment to excellence. In general, the application of real-time tracking systems in optical Fibre manufacturing equates to remarkable item top quality and raised consumer complete satisfaction.

Effect on Production Effectiveness

Carrying out optical Fibre Diameter analysers significantly boosts production efficiency by simplifying the production process. These tools facilitate continuous tracking of Fibre Diameter, enabling makers to spot discrepancies in real-time. By determining disparities quickly, production lines can be adjusted promptly, decreasing downtime and minimizing the possibility of producing malfunctioning items.

Moreover, the integration of these analysers right into the manufacturing workflow makes it possible for far better resource allocation. With exact Diameter dimensions, drivers can optimize product usage, ensuring that sources are not squandered on mistaken fibers. This precision additionally contributes to much less remodel and scrap, inevitably reducing manufacturing expenses.

The automation provided by optical Fibre Diameter analysers minimizes reliance on hands-on assessments, which are usually lengthy and vulnerable to human mistake. Consequently, staff members can concentrate on even more tactical jobs, boosting general performance.

Furthermore, the information generated from these analysers can notify procedure improvements and assist in far better decision-making. By evaluating fads in Fibre Diameter variations, suppliers can implement positive actions to enhance production strategies and keep consistent high quality. In recap, optical Fibre Diameter analysers play a vital duty in boosting production effectiveness, bring about better outcome and boosted productivity.

Case Research Studies and Success Stories

Throughout different fields, case studies highlight the transformative impact of optical Fibre Diameter analysers on production processes. One famous instance is a leading telecoms firm view that encountered obstacles with irregular Fibre sizes, bring about increased rejection rates. By incorporating an optical Fibre Diameter analyser, the firm attained real-time surveillance of Fibre measurements, leading to a 30% decrease in flaws and considerable expense savings.

Furthermore, a study organization concentrating on innovative materials made use of optical Fibre Diameter analysers to refine their experimental processes. The analyser's capability to supply thorough insights into Fibre consistency enabled the advancement of ingenious materials with better performance features.

These success stories emphasize the vital duty of optical Fibre Diameter analysers in boosting quality assurance, boosting production effectiveness, and driving technology across varied sectors.

Final Thought

In verdict, the Optical Fibre Diameter Analyser plays an essential function in improving high quality control within Fibre production. As demonstrated through various case studies, the analyser proves essential for achieving premium item top quality in Fibre manufacturing.

The implementation of optical Fibre Diameter analysers allowed for rigid top quality check my source control, making certain that the produced fibres met exacting industry standards.In final thought, the Optical Fibre Diameter Analyser plays a crucial duty in boosting top quality control within Fibre manufacturing.